With Generative AI guiding the path, AI is set to infuse a whopping $15.7 trillion into the worldwide economy. Analysts anticipate that by 2024, half of supply chain organisations will plunge headfirst into AI-powered applications and advanced analytics. As per insights from McKinsey, strategic deployment of AI in inventory management can lead to a reduction of up to 20% in inventory carrying expenses and a significant 50% decline in instances of stockouts.

In order to understand the cause and impact, this article will address the main challenges faced by today’s IT leaders and integration specialists in the Supply Chain industry, and explore the key technology trends such as supply chain management ERP enabling transformation, focusing on the use of AI to mitigate procurement and supply chain risks.

Challenges faced by IT Leaders in the Supply Chain Industry

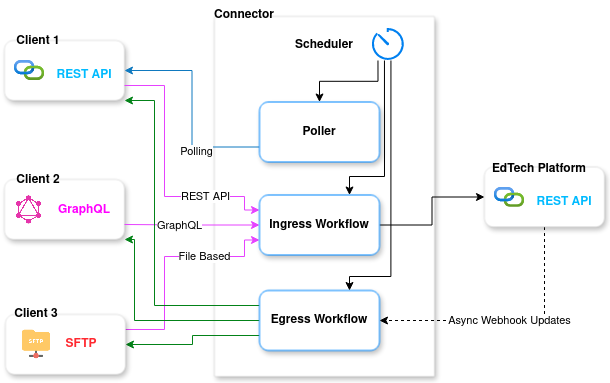

Complexity of Integrations

One of the foremost noteworthy challenges in supply chain advanced change is its integration complexity. The objective for IT experts in Supply Chain is to form and send applications all around, set up associations together with your favoured devices, whether online or offline, and execute them over different runtimes in any area, be it open cloud, private cloud, or on-premises.

Supply chains are complex frameworks that include numerous partners, counting providers, producers, wholesalers, and retailers. Particularly when it comes to 3PL and interfacing the bridge between clients and their end customers in certain scenarios such as for eCommerce businesses, integration plays a vital part in blending forms. Coordinating these stakeholders' frameworks and forms can be challenging, and may require extra layers of security and consideration to detail, requiring significant investment in time and resources.

More advanced approaches save important time for both company IT and remote development teams, who would need to devote time to setting up unused frameworks or interfacing existing ones beside their integration needs.

(Unused frameworks in supply chain management refer to predefined strategies or tools designed to improve operations but remain unused for various reasons. For instance, a manufacturing company invests in a sophisticated optimization framework, yet struggles to implement it effectively. One reason could be that the framework doesn’t align with the company’s specific needs due to differences in supply chain structures or operational challenges.)

Data Security and Compliance Issues

The cyberattack on the Colonial Pipeline in June 2021 showcased the serious results of deficiently cybersecurity measures, especially in information security inside the supply chain.

When a company offers information to suppliers, it is not in their full control of how that information is overseen, and vice versa. Contracts should outline the transfer of data security responsibility through binding agreements. Providers must maintain measures like encryption and access control. It is additionally fundamental to guarantee that obligations stream down to subcontractors. As the supply chain gets longer, responsibility for information protection compliance streams down the supply chain, meaning that an expansive undertaking can be responsible (and fined) for a breach by a provider.

Information security and compliance are basic concerns within the supply chain industry, given the delicate nature of the information included. Supply chains include the trade of touchy data, counting monetary information, client information, and intellectual property. IT pioneers must guarantee that information is secure, ensured, and compliant with important directions, such as the Common Information Assurance Control (GDPR) and the California Customer Protection Act (CCPA) and more.

Legacy Systems Hindering Operations

Numerous organisations in the supply chain industry still rely on legacy systems that are outdated and inefficient, waiting to be disrupted by modern technology adopters. These systems can be challenging to integrate with modern technologies, and they hinder operations. Apart from manual processes, inconsistent digitalization where parts of the supply chain are fully digitised while certain parts still follow excel sheets and manual data entering can hinder operations. These can sometimes be beyond the control of the IT leaders in the industry.

Another hindrance of operations in Legacy systems is Siloed Data. Employing an open-source platform with Master Data Management features, enables the seamless importation of data from suppliers through a unified mechanism, eliminating the necessity for specific IT systems. Automating the exchange of information throughout the supply chain reduces delivery and maintenance expenses while enhancing overall quality. Moreover, it mitigates the risk of vendor lock-in for both manufacturers and suppliers, as open formats facilitate data migration and tool integration effortlessly.

The Use of ERP and Cloud for Supply Chain Cost Control

Supply chain managers and leaders play a crucial role in overseeing all aspects of supply chains, aiming to achieve cost savings without compromising quality or timeliness. As stated by the American Public University, Enterprise Resource Planning (ERP) or supply chain management ERP systems serve as valuable tools. These systems offer a holistic view of supply chains, allowing businesses to monitor and manage operations in real-time, facilitating informed decision-making.

Cost is one of the biggest concerns that impact supply chain related decisions, and consistent supply chain efficiency relies on Data. Today, cloud capacity costs are rising, with most costs being allocated toward data storing, which is why ERP systems on cloud have become a feasible option for logistics and supply chain businesses. They reduce onboarding and maintenance cost and streamline supply chain operations by integrating various functions. But most importantly, they are capable of tracking and informing cost and expenses.

By leveraging ERP systems, businesses can pinpoint areas of excessive spending, inefficiencies, and potential risks, providing them with the insights necessary for successful budget control implementation.

To reduce operational expenses and increase better integration seamlessness, Ecommerce giants like Amazon are optimising their supply chain operations by leveraging cloud services. Amazon utilises Amazon Web Services (AWS), offering storage, computing, and database services for real-time data processing. This enables efficient supply chain management, undisrupted upstream and downstream processes, cost reduction, and enhanced customer satisfaction.

Amazon IRAS Incorporates Forecast for Supply Chain Optimization. Source: AWS

The Use of AI to Mitigate Procurement and Supply Chain Risk

AI-powered systems can analyse vast amounts of data, identify patterns, and predict potential risks, enabling organisations to take proactive measures to mitigate procurement-related issues and more. AI can be used to predict supplier disruptions, enabling organisations to take corrective action before they occur.

To mitigate procurement risks, one of America’s largest privately-held companies, are using an advanced AI solution to enhance their supplier optimization strategies. In contrast to conventional procurement methods that rely on broad purchasing categories and aggregate spending, this AI tool dives deep into detailed data, down to individual stock-keeping units (SKUs).

By using historical data to auto-fill new requests for quotes (RFQs) with key parameters such as lead times, locations, quantities, service-level agreements, and material costs, the AI algorithm learns from any modifications, improving its predictive accuracy over time. It is studied that this process saves suppliers 60% to 90% of the time typically spent on completing an RFQ.

![]()

The Use of AI to Boost Supply Chain Visibility

Is visibility a brewing challenge in the Supply Chain Industry? It is, despite the advancement of technology. That’s why expanding visibility beyond Tier 1 is crucial, enabling deeper insights into root causes, discovering risks further down the chain through improved traceability.

For example, AI can be used to track the temperature and humidity of perishable goods during transportation, ensuring that they are delivered in optimal condition. In addition, sensors, barcodes, RFID tags, and GPS devices, augmented data intelligence help in predictive maintenance, seamless communication, and streamlined operations.

AI-powered systems can provide real-time updates on the location, condition, and status of products, enabling companies to elevate their supply chain operations and improve customer satisfaction. Technological tools like control towers and digital twins can show critical sub-tier supplier relationships, increasing resilience.

The Use of AI for Advanced Purchase Order Management Systems

Manual purchase orders (PO) are prone to having errors from the slightest typo or to more serious inaccuracies in numbers. Automating and optimising procurement is the next best thing in supply chains. Unlike manual inaccuracies, automation ensures precision and uniformity in data, reducing the risk of misunderstandings and even duplicate payments.

Additionally these provide real-time tracking and monitoring of the procurement process if vendors are in the same platform or integrated to the same platform. Companies can utilise AP dashboards like Procure-To-Pay, to obtain a comprehensive overview of the status of their purchase orders, delivery schedules, and invoices, facilitating informed decision-making and prompt resolution of any arising issues.

AI Order Management Systems can potentially analyse the impact of delays on schedules and deliveries with good accuracy. Historical data, predictive algorithms and real-time information are some of the key factors these systems employ to assess the consequences of delays across supply chain networks. In scenarios as such, AI is capable of evaluating the impact on production schedules, inventory levels and also customer delivery times.

The interesting part is that AI can recommend fallback mechanisms to reduce the impact of delays and ensure minimal disruption to operations, including alternative sourcing strategies, sought-after shipping options, or dynamic rerouting of goods through different distribution channels.

Those with remote development teams that have built advanced PO systems have access to vendor management, and delivery tracking. Upon receipt of deliveries, it can automatically capture all pertinent data from the PO invoice through a validated data capture mechanism.

The Use of AI for Energy Saving

As much as technology is crucial for increasing profits and productivity, technology must also help empower environmental responsibility goals. According to KPMG, 5% of emissions in the supply chain stem from direct manufacturing, while those originating within it can be significantly greater, up to 5 to 10 times.

While this may seem like a responsibility primarily for sustainability leaders, It’s important for IT leaders alike to understand the necessity of reducing carbon footprint and how Scope 1 to 3 assessments work. Organisations around the world have embraced Hybrid Carbon Accounting methods to reduce carbon emissions, and this is largely based on the information of suppliers.

Vision of Global CTOs and CXOs

According to IBM’s global research data’s sample of 700 companies, 88% of the highest-performing organisations stated that AI is inevitable in their industry. Among those polled, fully 95% of the highest-performing organisations see AI as central to their innovation success. Will Gen AI lead this transformation?

Is your business looking to implement a Supply Chain Management ERP that addresses your very own unique problems? Build your solution with remote development teams that understand the technological necessities and your business background.

Determined to assist B2B enterprises in enhancing resilience and agility, we are actively seeking to broaden our service offerings to provide innovative solutions in this area, leveraging our extensive expertise in GRC, legacy system modernisation, and integration complexity. With Gen AI at the forefront, the global economy is set to receive a remarkable boost of £15.7 trillion. Embrace the state-of-the-art potential of AI applications and advanced analytics to transform your supply chain operations. From mitigating risks and improving visibility to optimising procurement and reducing environmental impact, the opportunities are boundless. The future looks promising, and the time for action is now!